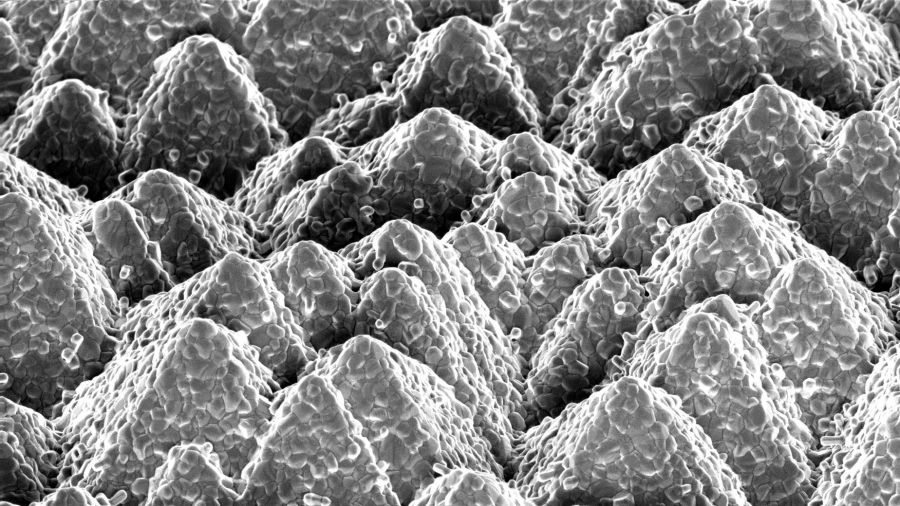

Dark-blue panels on red tiled roofs and green meadows – this is the image usually generated upon entering the term « solar energy » in an online search engine. The familiar blue solar cells made from silicon are indeed the most widespread technology for photovoltaics. For some time now, however, it has by no means been the only one. One new technology is about to get out of the starting blocks : the solar cell made from perovskite. This is the collective term for innovative materials whose crystal structure resembles that of the natural mineral also known as perovskite.

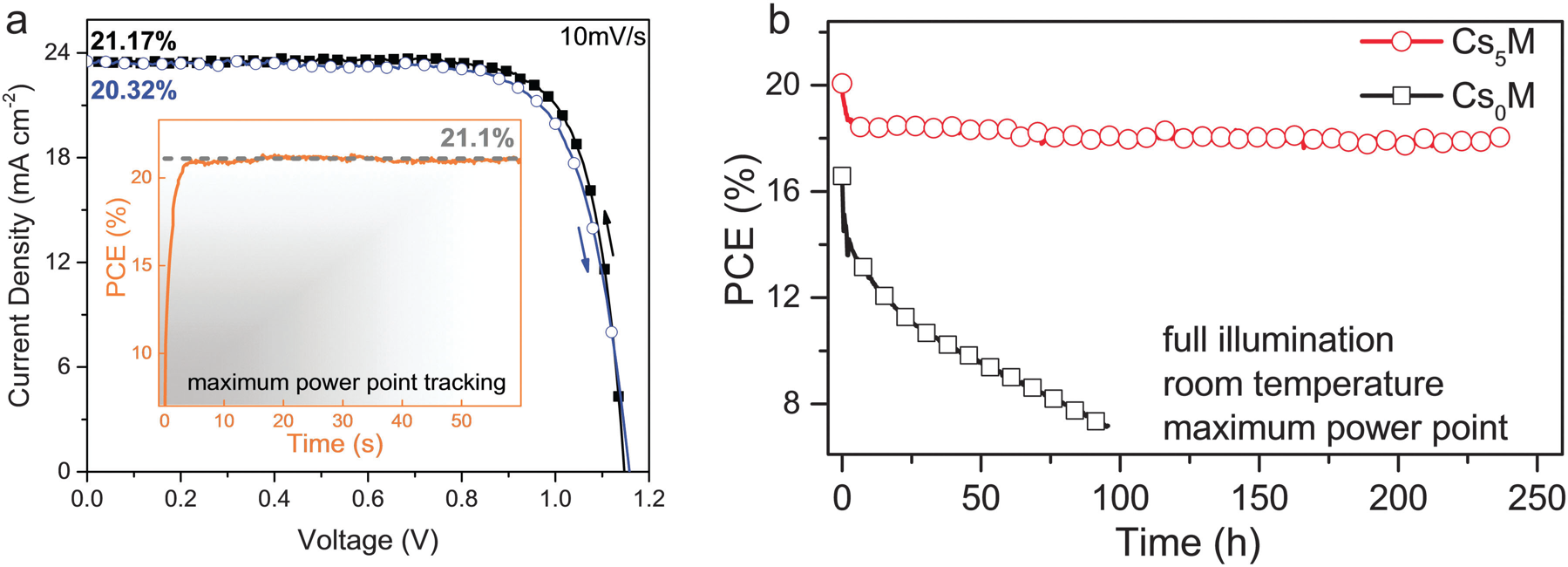

Perovskite solar cells have developed quickly. Over the past ten years, their level of efficiency has literally exploded and increased from a modest 3 % to more than 20 %. Perovskites have outstanding properties : they absorb light especially efficiently and are adept at routing the generated electricity. They are cost-effective as well as simple with respect to both production and processing. However, solar cells based on perovskites also have a significant downside : they do not yet work consistently enough and are not sufficiently durable for large-scale use. Researchers from the Swiss Federal Institute of Technology Lausanne (EPFL) and the University of Fribourg are working to improve the stability and efficiency of this promising technology.