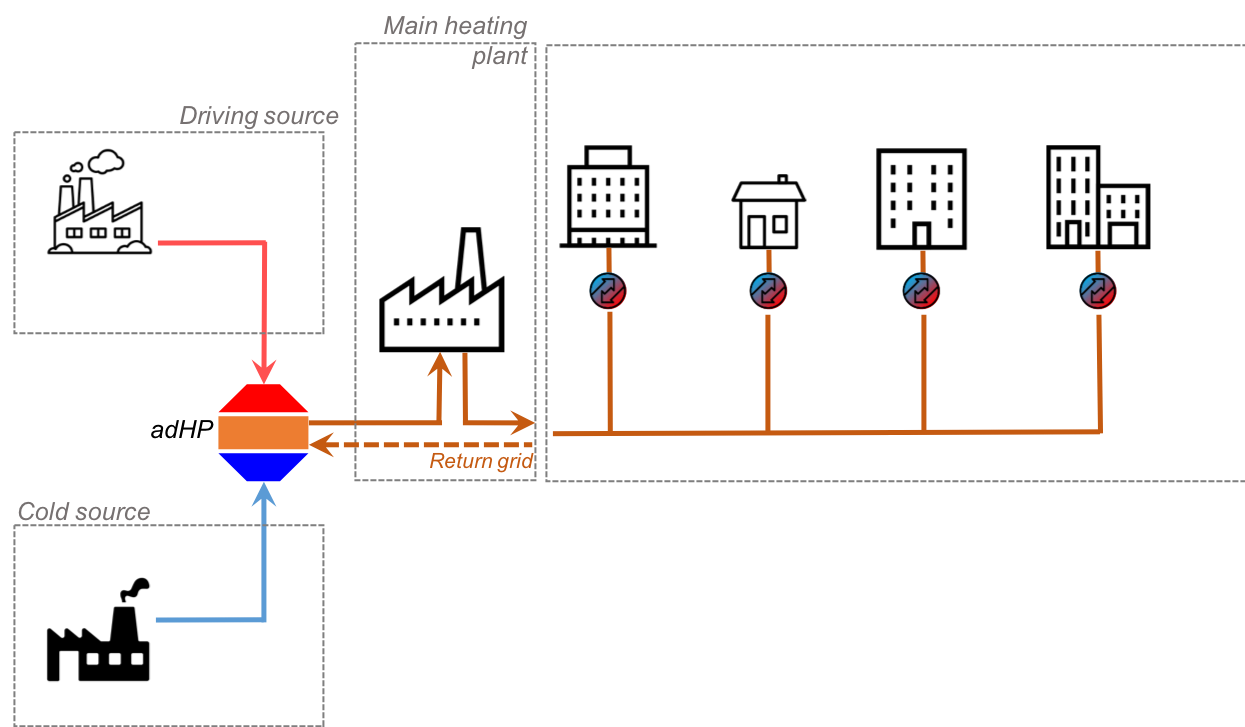

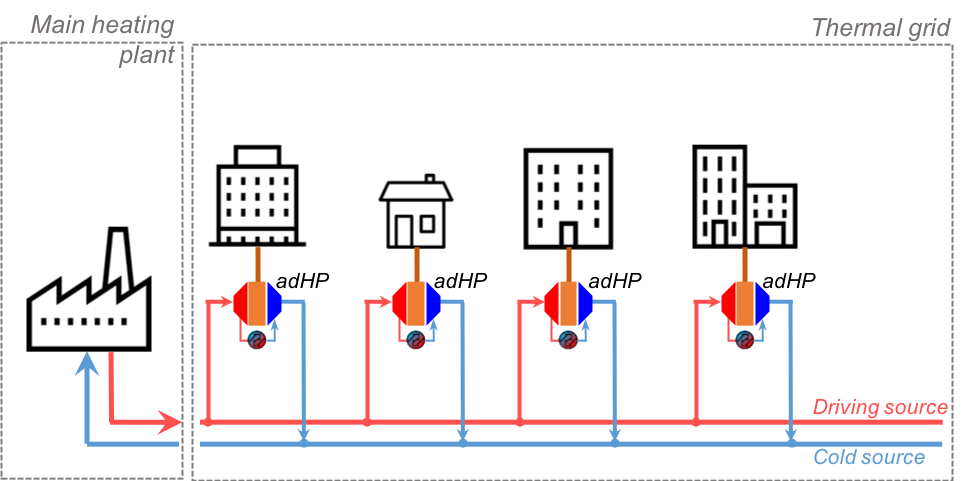

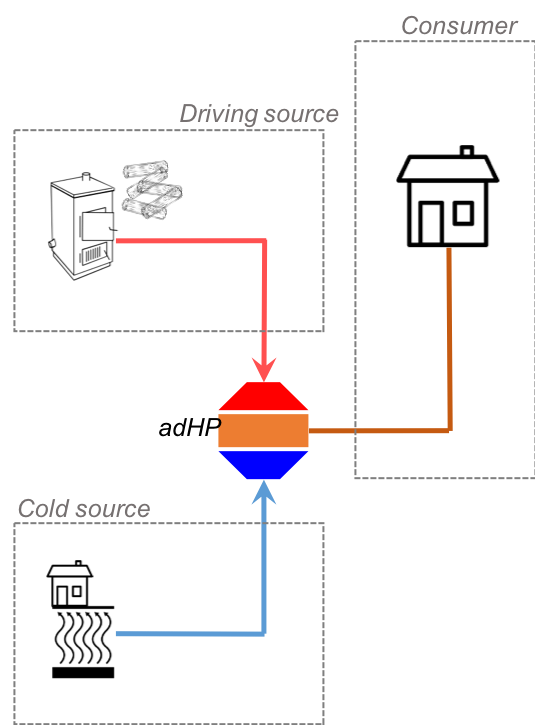

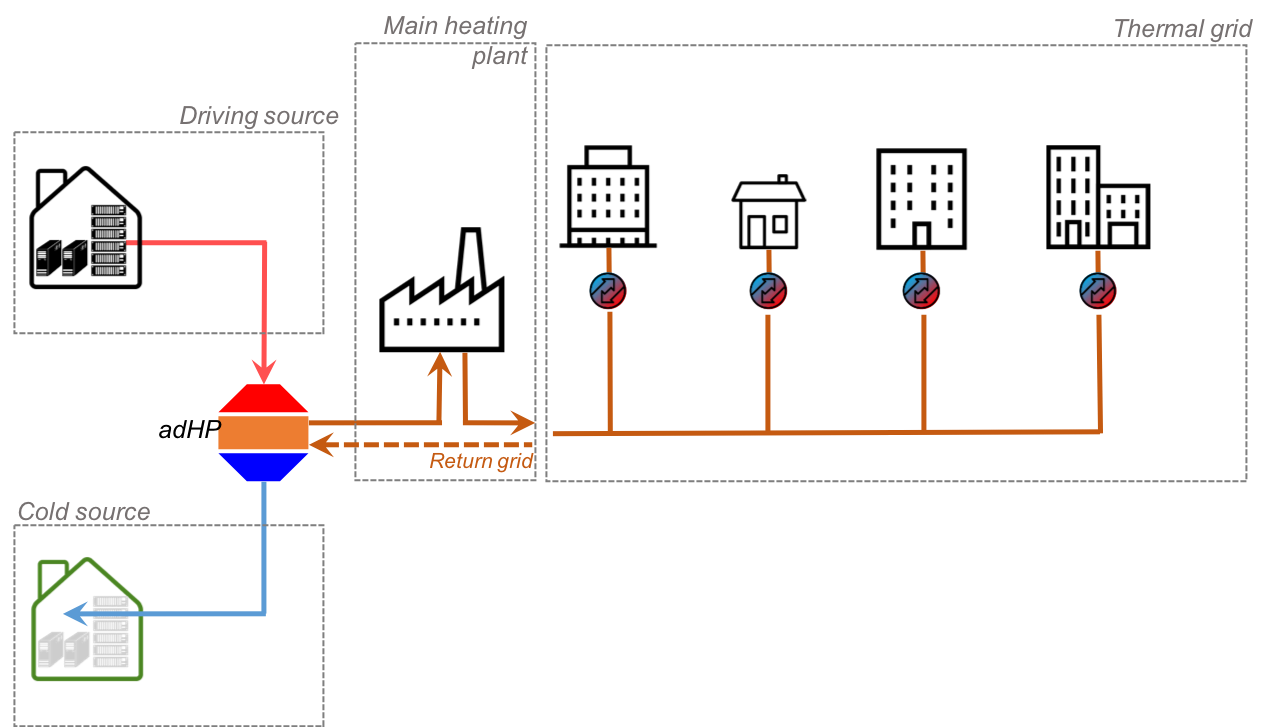

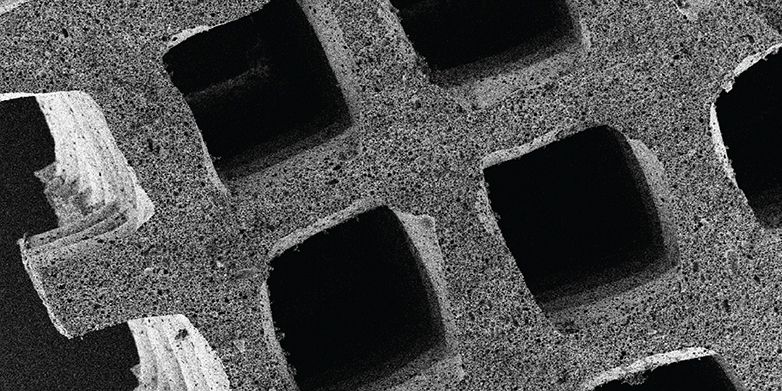

In Switzerland, a lot of energy is still lost in the form of waste heat. In some places, waste heat is already being used, for example from waste incineration plants. It can be used to heat buildings or even entire districts. However, valuable waste heat from factories or computer centres still escapes into the air. One of the reasons for this is that the temperature of the heat is often too low for it to be used directly. So-called adsorption heat pumps could help here in future. Similar to conventional compression heat pumps, they can collect and increase heat. Furthermore, adsorption heat pumps have an advantage over compression heat pumps: they require almost no electricity and instead use heat as a drive source.

Until now, however, the systems have been relatively expensive. There have also been no well-thought-out scenarios that showed in which existing heating infrastructures the systems could be best integrated. For this reason, Stéphane Citherlet, a physicist at the University of Applied Sciences and Arts of Western Switzerland in Yverdon, has worked together with his research team to evaluate possible applications in practice and to determine which technical requirements the heat pumps would have to meet in each case. The work was completed as part of the joint project “Heat utilisation with solid sorption technology” in which further sub-projects looked at the further technical development of the systems, their influence on the environment and their economic viability. The aim of the joint project was to develop the adsorption heat pumps as far as possible to market maturity.