Generating heat requires a great deal of energy: half of Switzerland’s total energy consumption can be attributed to the heating of our apartments and offices, the production of warm water and the drying or melting of materials as part of industrial processes. This energy still primarily originates from fossil sources. If we look at electricity consumption alone, 40 % is used for the heating and cooling of rooms or materials – around half of this electricity is currently still produced by nuclear power plants.

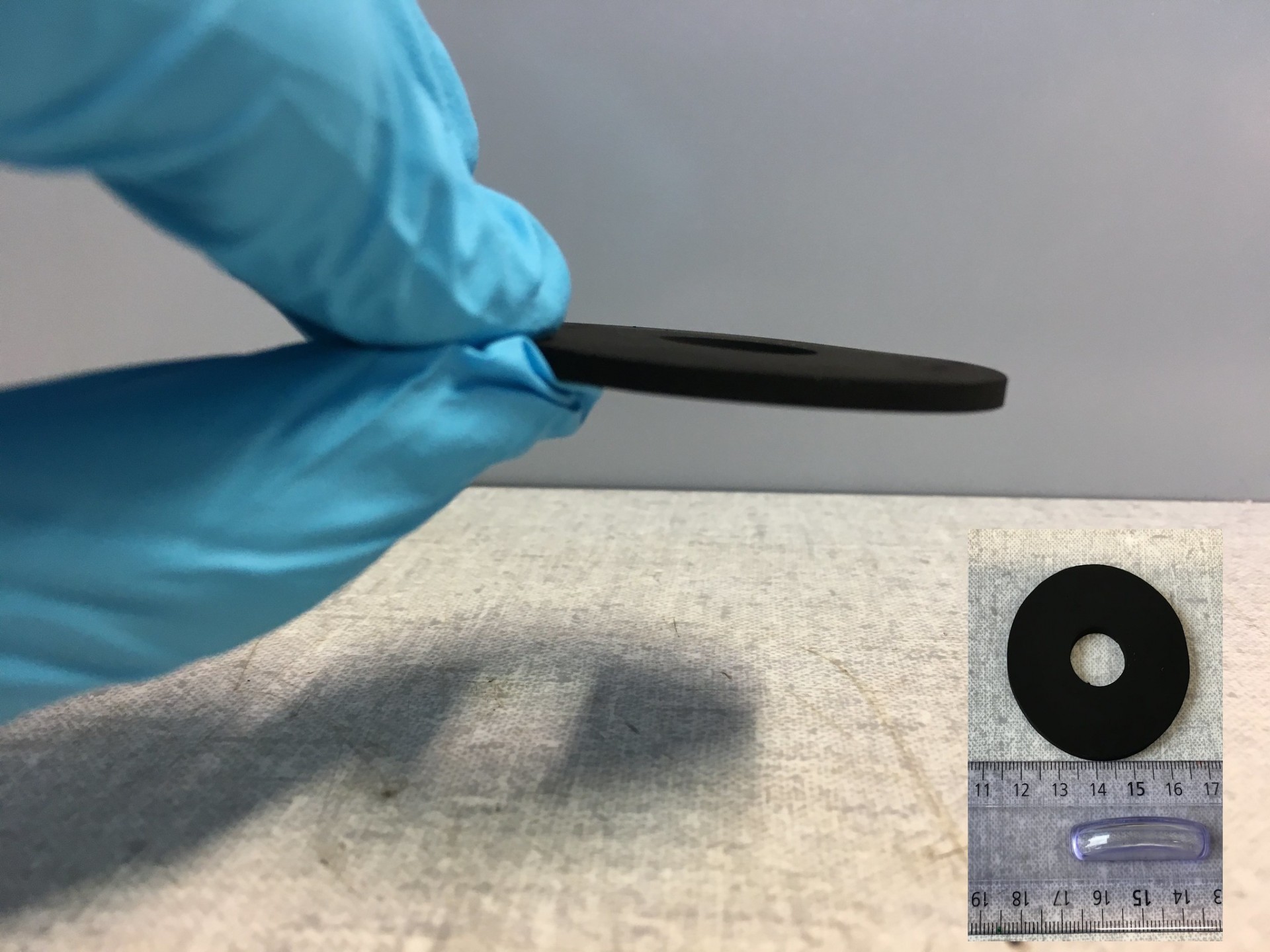

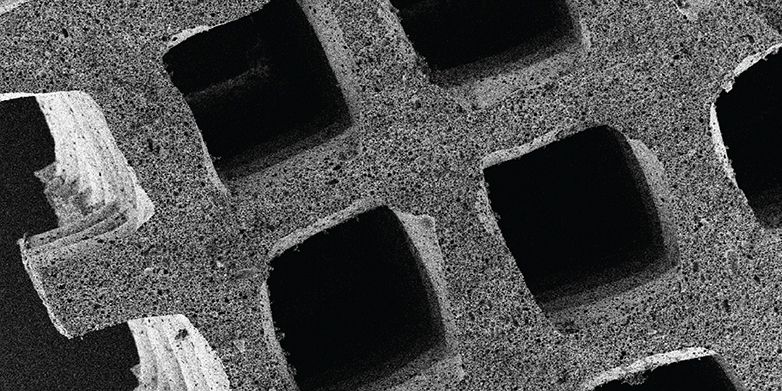

This has to change in future as Energy Strategy 2050 states that CO2 emissions should be reduced and nuclear power should disappear as a source of electricity. Bruno Michel, a computer engineer at IBM Research, therefore states that “we need to start using our resources more efficiently”. He views heat pumps, which utilise energy from previously unused waste heat, as an option here. Together with his colleagues at IBM Research and the University of Applied Sciences Rapperswil, he has further developed so-called adsorption heat pumps as part of a joint project.