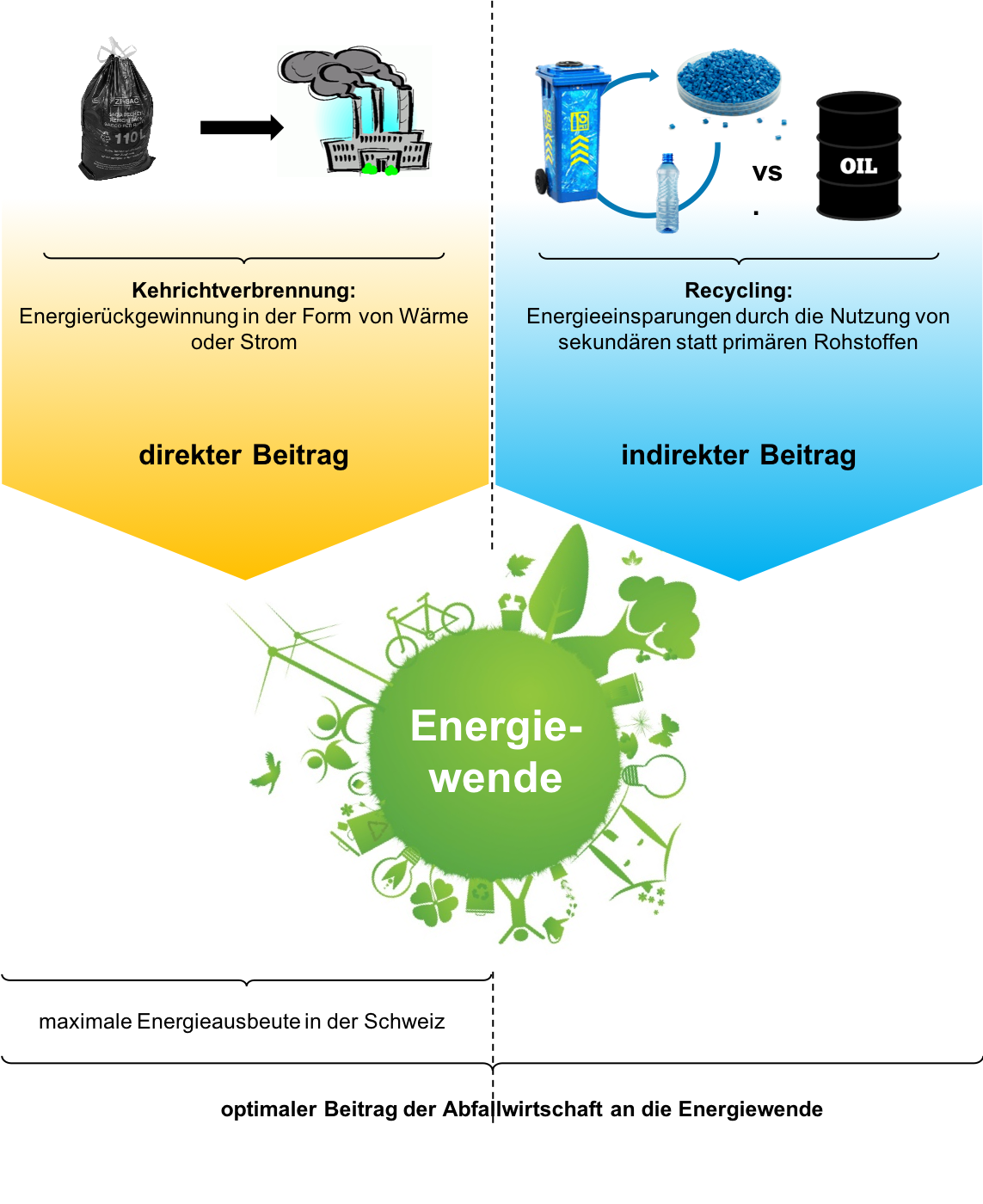

Waste is not useless rubbish. Energy that can be recovered is contained in the variety of waste from Swiss private households and the industrial sector. This already takes place through the use of heat and electricity from incineration plants and the recycling of materials – including paper, cardboard, glass, metal, PET, organic waste and, to some extent, plastic. However, a great deal of energy is still lost in the recovery chains. “This could be changed by optimising waste management to ensure that it yields the greatest possible amount of energy and has the smallest possible negative impact on the environment”, says Stefanie Hellweg, an environmental engineer at ETH Zurich. “This would allow waste management to make a much bigger contribution to the energy turnaround”. Together with her research team, two other teams from ETH Zurich and a team from the University of Applied Sciences and Arts Northwestern Switzerland, Hellweg investigated what would be required to this end as part of a joint project.

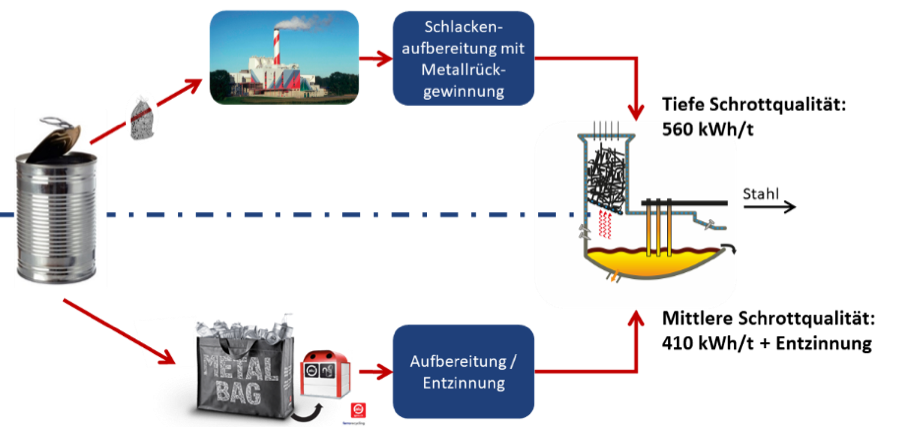

The researchers initially determined what waste is actually being generated in Switzerland and what is happening with it in the existing recovery processes. They conducted material flow analyses and energy flow analyses for all waste recovery processes in Switzerland and in doing so recorded all transport and storage processes as well as all energy flows within the recovery chains. They also modelled all recycling and incineration processes using computers. Moreover, the environmental engineers calculated all environmental impacts of the various types of waste and their recovery in a total of 190 life cycle analyses. This allowed them to simulate the influence of possible optimisation measures in a targeted manner.