Based on the federal Energy Strategy 2050, Switzerland will gradually shut down its nuclear power plants over the next few decades. Consequently, the large input sources currently feeding power into the electric grid will no longer be available. At the same time, the number of photovoltaic and wind power plants feeding small and inconstant amounts of electricity into the grid will increase.

This progression from a few centralised power plants to a large number of small decentralised plants poses new challenges: the power grid depends on a constant adjustment between the power needed and that provided by the power plants, in order to ensure constant mains frequency and voltage regardless of fluctuations in consumption and feed-in.

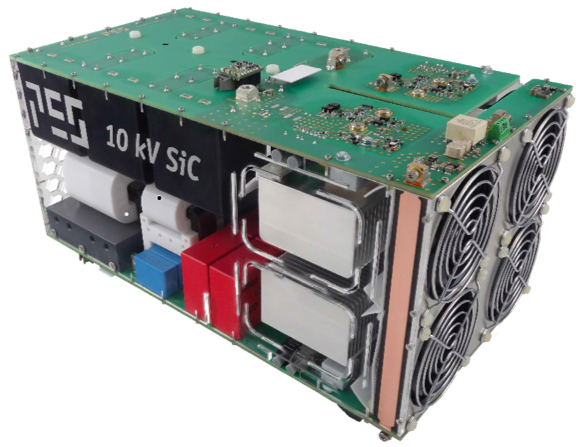

New power electronics, such as components that can raise or lower the electrical energy in the grid to a desired voltage, or so-called rectifiers and inverters that turn alternating voltage into direct voltage or vice versa, are a must to achieve this.