Switzerland's CO2 emissions must be reduced in the future – this is a requirement of Energy Strategy 2050. One step towards achieving this goal is to use the resource of heat more efficiently. The heat we need to heat buildings, produce hot water or dry and melt materials in industrial processes accounts for half of our total energy consumption. And this energy still primarily originates from fossil sources such as crude oil and natural gas.

Heat energy could now be used more efficiently by recovering and reusing more waste heat than before. This is made possible by so-called adsorption heat pumps. Similar to conventional compression heat pumps, such systems can collect and upgrade heat. In contrast to conventional heat pumps, they require almost no electricity to this end. Instead, they use the heat as a drive source. The process works from an input temperature of 35 to 60 degrees Celsius. For example, adsorption heat pumps could obtain waste heat from factories, computer centres or renewable heat energy from thermal solar plants. However, assessments of their impact on the environment and their economic viability have so far been lacking. Researchers from the Technology Assessment Group at the Paul Scherrer Institute (PSI) have now changed this and created a comprehensive sustainability assessment.

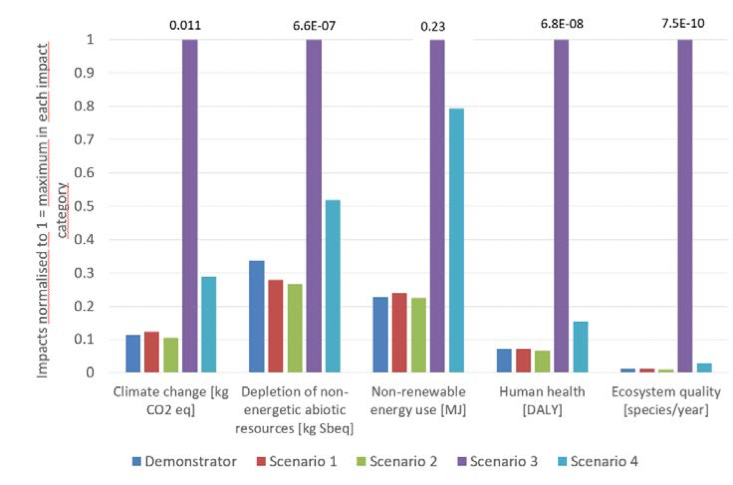

On the one hand, they have drawn up a life cycle assessment in which they analysed the entire life cycle of an adsorption heat pump – from its manufacture right through to its ultimate disposal. On the other, they carried out detailed cost calculations. “With these assessments, we have created a decision-making basis for the future introduction of the systems”, says Peter Burgherr, who headed up the project. “This allows for the advantages and disadvantages of different usage strategies to be identified. It also enables us to compare the systems with other, already established technologies”.