Space is at a premium in Switzerland. If free land was to be used to achieve the Energy Strategy 2050 objective of generating 20 % of energy via photovoltaic installations, conflicts would quickly arise with the agricultural sector, while concerns with respect to forest areas, wild animals and the leisure needs of Switzerland’s citizens would also come to the fore.

Photovoltaic systems must therefore be placed on buildings. While there is sufficient space in Switzerland to this end, it will not be enough to simply equip the roofs of new buildings with photovoltaic modules. The roofs of renovated buildings as well as their facades must also be utilised for electricity production.

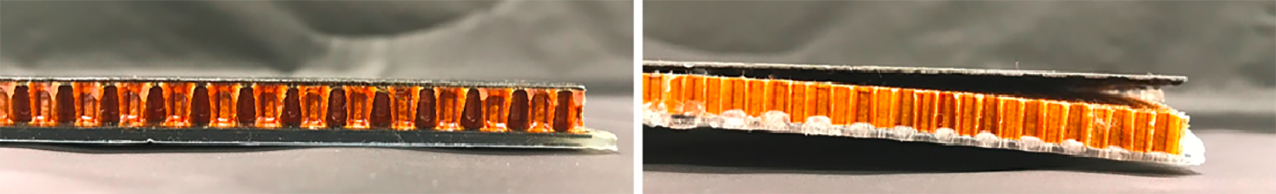

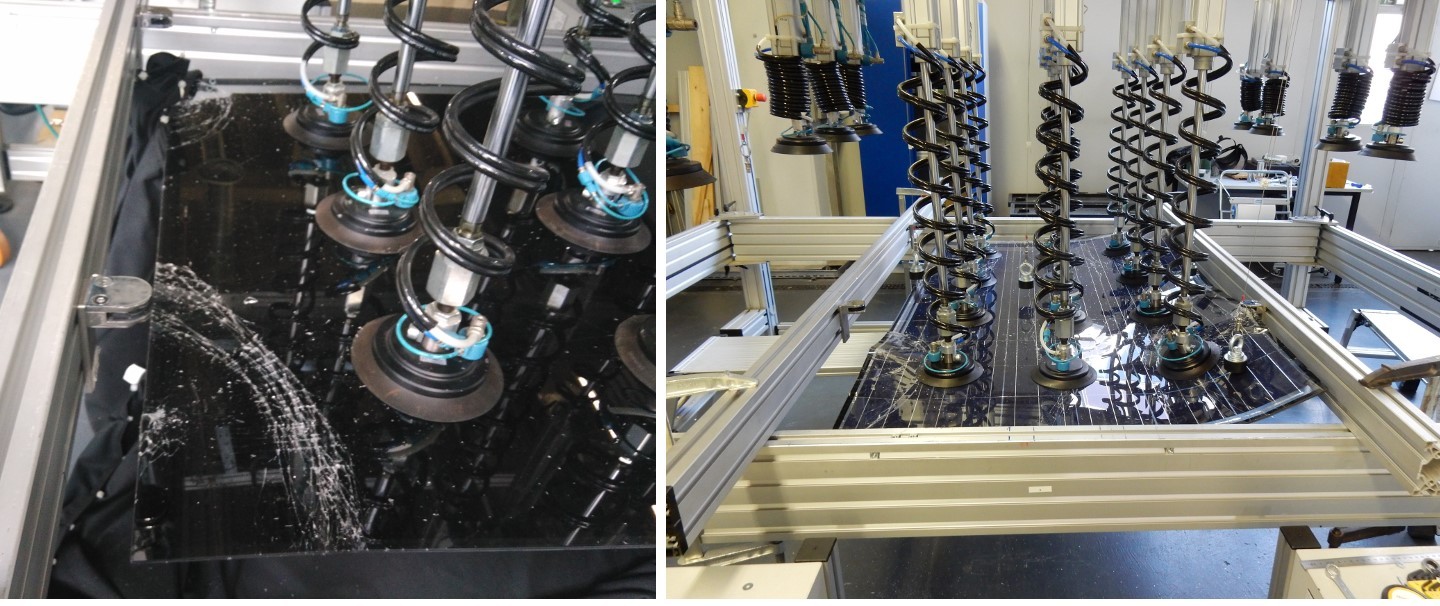

The technology required for building-integrated photovoltaics (BiPV) is actually already available. It is therefore now possible to integrate photovoltaic modules in roof tiles or facade elements. Nevertheless, such systems are almost nowhere to be found. Many building owners are put off by the higher investment costs, while architects are not convinced of the aesthetics of BiPV products – or have not yet come into contact with solutions that convince them.